Технологии

Технология ОСРК

Полный текст предоставляется по запросу

The CROCS Technology (©NATI Research) is the Technology of Correct Reflection of Ore Component Structure. Basically, it is a consistent hierarchical complex of many interrelated blocks and elements. The primary function of this Technology is the obtaining of correct authentic information about natural distribution structures of components (ore components included) in loose sediments, solid rocks and ore deposits of the explored target or area.

The correct reflection of ore component structures (i.e., the CROCS Technology) finds application in different spheres: in ecology, environmental monitoring, land use and geology. Each of these spheres requires adequate authentic information about the distribution structure of components (including ore components) in loose sediments or solid rocks. This should be specially stressed, as sometimes the CROCS Technology is erroneously regarded as one among a variety of numerous geochemical exploration techniques, while it is not true. Exploration is one of the spheres of CROCS Technology application, but not the contrariwise.

In the sphere of geology, the CROCS Technology is applied at all stages of geological survey of areas and geological objects. According to the subdivision of the entire process of geological survey on territories and to delineation of ore bodies, the study includes (taken from "Exploration and Mining in Finland's Protected Areas, the Sami Homeland and the Reindeer Herding Area; Guide". Ministry of Trade and Industry Publications, 30/2007):

"Survey process

Exploration can be divided as follows:

1 area selection,

2 regional survey,

3 targeted survey,

4 deposit survey".

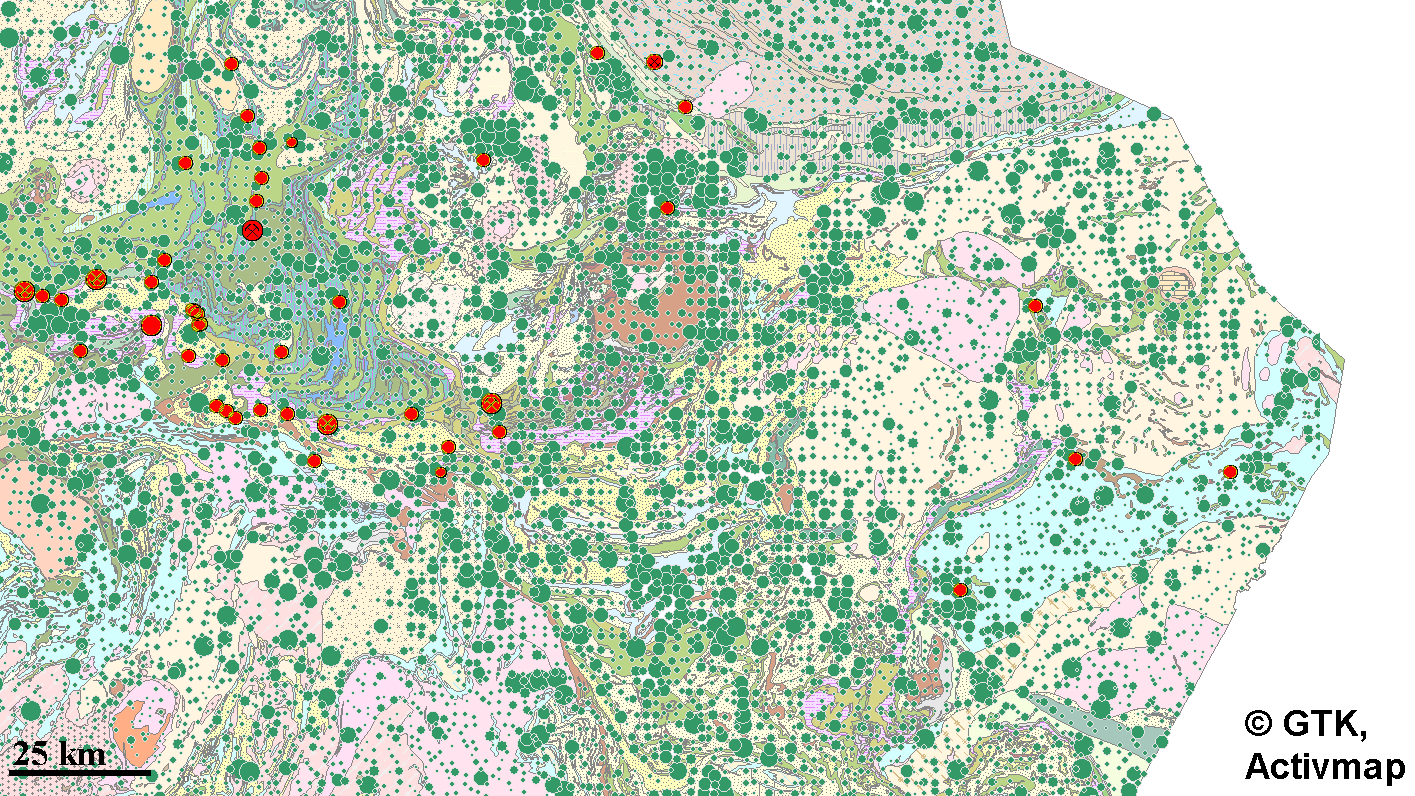

Application of the CROCS Technology at each listed stage has its own specificity which is determined by geological peculiarities of the surveyed area and operation scale. Nevertheless, regardless of specifics of the CROCS Technology application at each stage, the aim of its use remains the same, which is the correct reflection of components distribution structures. It means that the result data of the CROCS Technology application at each stage differ in values; however, they (data) share a common feature – the authentic reflection of natural object properties. This latter aspect is the major advantage of application of the CROCS Technology in explorations that differentiates it from all traditional widely practiced geochemical exploration techniques. The incorrect reflection of ore component structures is a well known problem (Fig. 1), and its analysis and determination of remedies is one of the objectives of the CROCS Technology.

Figure 1. Structures of gold distribution in overburden (green proportional circles, secondary haloes) and verified gold in solid rocks (red proportional circles). Low correlation between the red and green circles. IF < 5%.

|

Metallogenic zonation of the territories and justification of the perspective ore localities are being provided in addition to the general geological exploration of areas at the Regional Survey and Targeted Survey exploration stages. There is no doubt in the necessity of application of the CROCS Technology in order to obtain the reliable data of ore component distribution structures to serve as the basis for metallogenic zonation and identification of local ore perspective areas on the next stages of survey process (including the Deposit Survey). However, the metallogenic zonation alone is not sufficient for the Targeted Survey stage. Therefore, the CROCS Technology has been adapted for solving the prospecting task (i.e., delineation of ore targets), by incorporating an additional logical block – proving the presence of secondary dispersion halos among the identified geochemical anomalies. Reference: the proven presence of the secondary dispersion halo in loose sediments is the direct evidence of the ore mineralization in the underlying bedrock, and the further search at the Targeted and Deposit Survey stages should be executed on the primary dispersion halos in bedrock.

The CROCS Technology application is most effective at the Deposit Survey stage and during the resource-reserve assessments. Application of this technology at these stages is necessary for:

- 3D mapping of natural ore varieties;

- large-volume samples preparation for pilot testing;

- 3D mapping of different technological ore types;

- determining cut-off boundaries of ore bodies, and boundaries of technological ore types upon the requirement of the sensitivity equality for each sub-variety.

Technology application in exploration works. The CROCS Technology: a close-up glance.

The main blocks of the CROCS Technology are presented in Fig. 2. It follows from the diagram that the end product (i.e., the correct reflection of ore component structure) is an information product yielded by a process that logically may be regarded as a ‘measurement’.

Figure 2. Groups and blocks of CROCS Technology.

|

The result of any measurement is the numerical value of the measured parameter (e.g., elemental chemical composition of a sample or a set of samples collected on the explored territory) plus/minus the measurement error. Accuracy of the performed measurements is determined by the error value (the total error is calculated by multiplying error values from each stage of measurements). Therefore, even a rough error evaluation (even qualitatively) is that unique parameter that characterizes the end product quality. Strictly speaking, the absence of error means the absence of the result of measurements. The measurement activities are not equivalent to the result of a measurement and do not ensure that correct results are obtained. In such case, the results of measurements are negligible (see Fig. 1). The above-mentioned is not an invention of NATI Research; these are fundamental statements of such interdisciplinary approach as the Theory of Measuring.

Each link of a technological chain transmits without distortion only a part of the initial information. Transmission factor (TF) of any link will always be less than 100% because of the transmission error presence.

Multiplication of TF of all the technological chain links will show total part of the primary information represented in resulting documents. In terms of CROCS Technology, the Concordance Factor (CF) = TF1·TF2·…·TFn shows that total part of initial information, which is correctly reflected in the final results. So, final result may be referred as the information replica of the a natural object, which had been studied with quality level equal to CF.

Also, the Identity Factor CF is the parameter of quality assessment of any exploration project (both: proposed or finalized project).

As an example, let's assume that for geochemical exploration task, the technological chain consists of five links, each of the link transmits the ore component contents only partly, but for 90% (it is quite high TF value). The CF value will be: CF = 0.9·0.9·0.9·0.9·0.9 = 0.59 (59%). So, despite high values of TF - only 59% of the initial information will be correctly present in the final result. Considering this, we shouldn't wonder that CF < 5% is the regular case for traditional approaches of geochemical exploration (see Figure 1).

For each particular study the customer predefine the CF before the study. According to the predefined CF value, the informative prospecting parameters, and their values, are being chosen and calculated. It is obvious, that the higher CF is chosen, the higher budget is required. Such approach allow the obtaining the reliable results with the predefined level of work quality (the IF), as well as, allow to evaluate the efficiency of works, including the economical efficiency.

The CROCS Technology has the 'Metrological Base' block as the basic unit (Fig. 2). Metrological Base is the theoretical basis, upon which all elements (links) of the technological chain can be grounded at the 'Projective Technology' stage, and the technological chain itself can be created such way, that it will ensure the result data to be obtained in strict accordance with the predefined CF.

The Projective Technology stage envisages selecting exploration parameters, calculating their numerical values and specifying error values for technological chain elements in accordance with predefined CF. Under term “exploration parameters” here means such ones like commodity signal, satellite signals, work sensitivity (not the same as analytical sensitivity), properties of sampling network, representative sample weight, way of sample collection, way of sample field and laboratory treatment, analytical techniques, compilation and reporting methods and so on. To this end, all geological peculiarities of the exploration area are taken into account. If the available geological data (geological, topographical, quaternary, metallogenic and other maps, regional prospecting data and so on) are insufficient for determining the exploration parameters and calculating their numerical values before the initiation of works, these data should be obtained at the Foregoing Preliminary stage of the ‘Projective Technology’ block by means of collecting and analyzing a limited set of samples beforehand.

It means that it is impossible to apply any uniform exploration working scheme (sample type, sampling technique, samples pretreatment in field and laboratory, chemical analysis type) in all possible geological situations at any possible scale of activities. Under conditions of a specific exploration area, application of such a uniform scheme will yield incorrect results or, at best, its application will not be optimal in meaning and economically.

The 'Implementation and Instrumentation' block of the CROCS Technology is the block within which the appropriate and necessary equipment, materials, methodology and executives skills will be chosen for each link (stage) of the technological chain. As well, the whole works workflow (technical order) will be set up within the block.

The 'Tasks and Jobs' block is actually a block, where the step by step sequence and timing of works will be built. In other words, the particular scheme (technical order) of work will be obtained, but in accordance with the particularity of the prospecting/exploration area, customer requirements and CF. In order to obtain the result data which will fulfill all the set before conditions (IF, customer requests and so on), the work has to be performed in strict accordance and without any violation of process regulations (technological order).

As the result of these procedures, all required elements are identified, process regulations worked out and the quality level (CF) of the informational end product is specified. This will serve as a basis for calculating the cost of this particular product with the specified quality level. (It is no secret that in practice quite an opposite occurs too often when the amount of funding is determined prior to the amount of work. In such a case, the CROCS Technology serves as a useful tool for calculating the end product quality (CF) that should be expected with the provided amount of funding. Also, the CROCS Technology may be used for evaluating the quality of the data and results, as well as of the previously obtained data (e.g., those in Fig.1).